Firefly 44

- Matthew Nguyen

- Sep 1, 2021

- 3 min read

Updated: 2 days ago

As a PC hardware enthusiast, some of my favorite builds are Small Form Factor PCs. I enjoy the challenge of fitting components in as small a package as possible while still being able to properly cool all that power and heat output. My most insane build was that for my own PC for use at Stanford.

The design for the case was made in Fusion360 and to date remains my most complex single CAD assembly.

Models for most standard parts were pulled from GrabCAD, however, it started to become apparent as the design progressed that fewer and fewer of the parts included were actually common and required very specific hardware in order to make the build work. This was also my first time working in the sheet metal design tool

The sheet metal parts for the case were bought from send cut send with the majority being 1.5mm aluminum. The bends were made manually on a sheet metal brake, while the tabs on the 3mm thick motherboard plate were bent manually with a pair of pliers.

The 3d printed parts were printed in Onyx on a Markforged Mark 3.

The case assembly was quite trivial compared to the overall scope of the build. The real tricky part will come from fitting all the components into the case

The cooling solution needed to less than 33mm in height. The heatsink was able to cool 120W, which allowed the CPU to be overclocked to 4.8GHz.

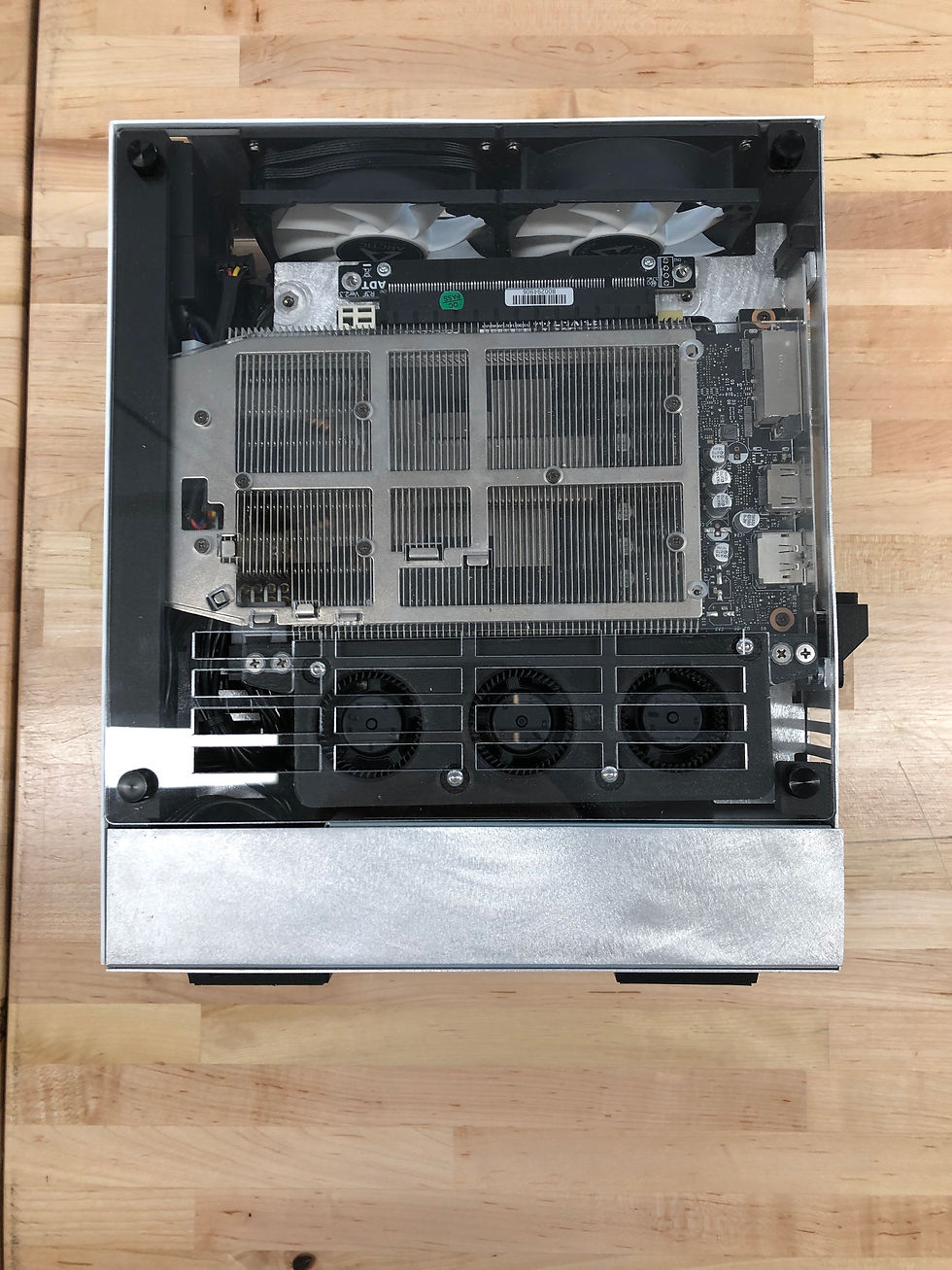

The graphics card had to be modified to be a single slot design so that the case was able to be reduced to a width of 80mm. To do so, I scavenged 3x 55mm centrifugal fans from old projectors and 3d printed a custom air duct shroud in order to blow air across the height of the graphics card. This cooling solution proved to be just as effective as the stock cooling solution while reducing the total volume of the case by 1 liter.

The case was designed around using a unified exhaust system for both the CPU and GPU sides of the case. This greatly increase the cooling performance for the given volume as the exhaust fans are able to exhaust hot air from both the CPU cooler and GPU cooler. Air is intaked from both sides of the case using the fans on the CPU cooler and GPU cooler then exhausted out the other side of the heatsink directly into the exhaust fans. This additionally reduces the need for air to be redirected as it hits the bottom of a heatsink as the air can fully flow through the length/height of the heatsink. Because of this, believe it or not, the case performs better with the side panels on than off.

The power supply was a Flex ATX form factor power supply that was modified to support a modular ATX interface in order to properly power the computer. This was one of the scariest mods that I have done for PC hardware given the amount of current and voltage the large capacitors were capable of. In the case, this has its own channel for cooling that is isolated from the integrated cooling system in order to give the power supply its own fresh air.

All in all, the case has a total volume of 4.4L, hence the name Firefly 44.

Comments